Can You Paint Any Floor With Floor Paint?

A UK guide to choosing the right coating, preparing your surface properly, and applying for a durable, professional finish—at home, in garages, or across commercial and industrial spaces.

Quick Answer

Wondering if you can paint your specific floor—and what to use? Start here:

Yes—most floors can be painted if you select the right coating for the substrate and prepare it properly. Concrete typically suits epoxy for maximum durability and chemical resistance, but epoxy sits at a cost premium. Where budgets or duty levels differ, polyurethane (PU) and EverFlor AQ water-based acrylic can be smart, lower-cost choices—especially for lighter duty or where flexibility/low odour is a priority.

How to decide in 30 seconds—ask yourself:

- What’s the substrate? Concrete, wood, tile/laminate, or power-float affects primer and topcoat choice.

- How tough does it need to be? Heavy traffic, hot tyres, oils/chemicals → lean toward epoxy; moderate duty → PU often balances cost and durability; light industrial duty/refresh work → EverFlor AQ.

- Budget vs performance? Epoxy is the performance leader (and pricier). PU is a robust, cost-effective alternative. EverFlor AQ keeps costs/odour down for light industrial and domestic spaces.

- Odour & downtime limits? Need quick turnaround/low odour? EverFlor AQ (Matt/Satin) is ideal; water-based epoxies also help where specified. We also offer a full range of fast cure epoxy topcoats and primers to facilitate 1-day prime and coat when needed for a specific job.

- Any moisture or contamination? Damp/oily concrete may require the right primer (e.g., DT/OT/PF/EW depending on the issue) before your chosen topcoat.

Rule of thumb: Epoxy = maximum durability/chemical resistance. PU = tough, flexible and great value. EverFlor AQ = clean, quick light industrial/domestic upgrades with low odour (pair with Prime AQ).

Still unsure? Tell us about your floor and we’ll recommend a system.

What Is Floor Paint?

Floor paints are specialist coatings engineered to resist abrasion, tyre pick-up, chemicals, oils and frequent cleaning. Compared with wall paint, they deliver stronger adhesion, higher film strength, and better long-term wear—essential for garages, workshops, warehouses, and busy household areas.

In other words, floor paint isn’t just about colour—it’s about protection and performance. A properly specified coating provides a hard-wearing film that bonds tightly to the surface, forming a barrier against mechanical wear and everyday spillages. Whether you’re protecting a domestic garage, a factory floor, or a retail space, choosing the right floor paint extends the life of the substrate and reduces the cost and hassle of constant maintenance.

- Durability: resists scuffs, scratches and wear from foot traffic, trolleys, and vehicles.

- Chemical resistance: stands up to oils, fuels, brake fluid, cleaning chemicals, and industrial spillages.

- Cleanability: smoother, sealed surfaces are easier to keep hygienic and dust-free.

- Finish options: matt, satin, gloss and anti-slip textures to balance appearance with safety.

Because floors face harsher conditions than walls—heavy machinery, hot tyres, dropped tools, and constant cleaning cycles—ordinary paints won’t last. Floor paints are formulated with resins and additives that provide the necessary strength, adhesion, and resistance to cope with these demands. The result is not only a better-looking floor but also a safer and more cost-effective environment long-term.

Can You Paint Any Floor?

It’s a question we hear often: can every floor really be painted? The short answer is yes—but only if you choose the correct system for the surface and how it’s going to be used. Floors vary hugely in what they’re exposed to: a light-use spare room, a busy household kitchen, a domestic garage, or a heavy-duty industrial workshop all put very different demands on a coating.

In principle, yes. The key is to match the chemistry to the substrate and traffic level, then carry out the right prep. Epoxy is the performance leader on concrete (especially garages and industrial areas) but costs more. PU provides an excellent, often more economical balance of toughness and flexibility; EverFlor AQ gives a low-odour, quick-dry solution for light-to-medium duty where budget and turnaround matter.

To put it another way:

- Concrete floors: Epoxy is the premium choice for maximum durability and chemical resistance. For projects with tighter budgets or less extreme loads, PU is a solid option.

- Wooden floors: PU systems offer the right flexibility to move with the timber without cracking.

- Laminates or tiles: These need a specialist primer first (such as EverFlor Laminate or Porcelain Primers) before applying a compatible topcoat like AQ or PU.

- Green or power-floated concrete: These need the right primer (Prime EW or Prime PF) before you can apply the main coating.

The main limitation isn’t whether a floor can be painted—it’s whether you take the time to use the right primer, coating and preparation steps. Do that, and nearly any floor can be transformed into a surface that looks better, lasts longer, and is easier to maintain.

If you’re unsure, tell us about your floor (size, substrate, condition, moisture, temperature and traffic) and we’ll specify a system.

Types of Floor Paint (When to Use Each)

Epoxy (100% Solids & Water-Based)

100% solids epoxy gives high build, superb adhesion and chemical resistance—ideal for garages, workshops and industrial areas where maximum performance is required. Note: epoxy carries a higher material cost than PU or AQ.

Water-based epoxy (EverFlor WEP family, launching) offers lower odour, quick re-coat windows and easier application, including Prime 4H rapid variants based on a 100% solids epoxy formula for fast return-to-service.

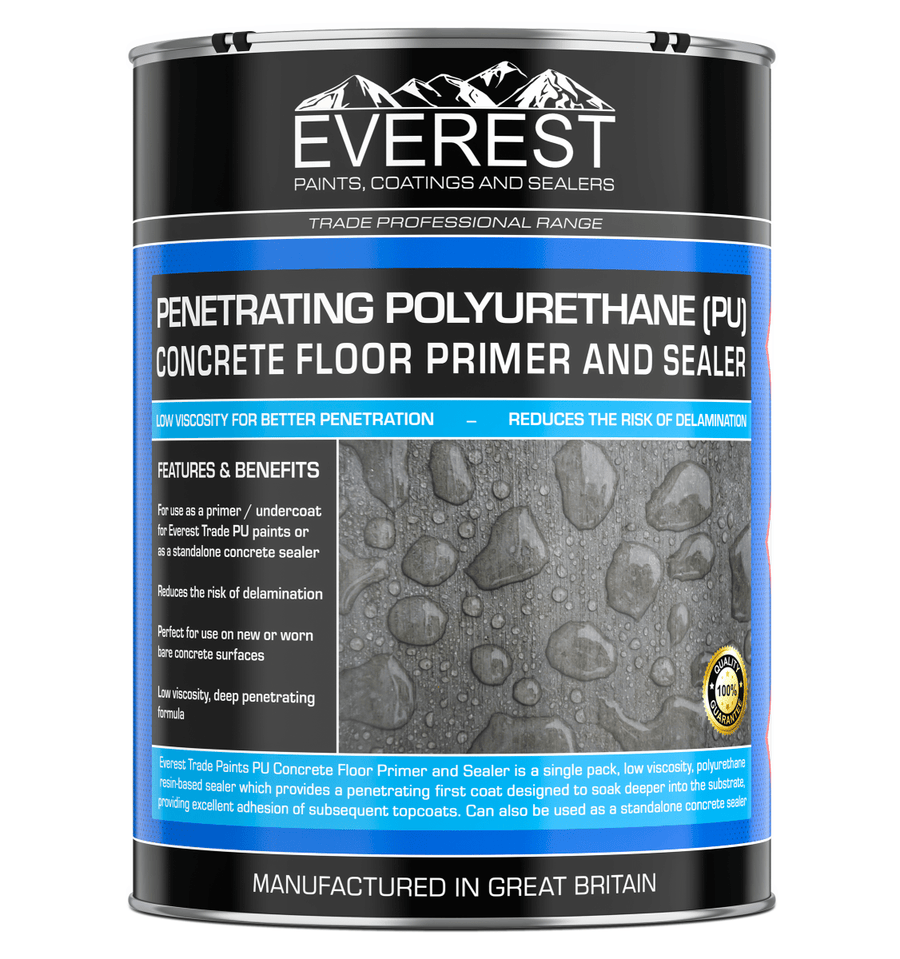

Polyurethane (PU)

PU provides excellent abrasion resistance with a tougher, slightly more flexible film—great for wood and commercial floors. It’s often a cost-effective alternative to epoxy when extreme chemical resistance isn’t required. Our 1K solvent-based PU is available now; EverFlor PU Garage/Industrial/Wood (Gloss & Matt) expands the choice.

EverFlor AQ (Water-Based Acrylic with Silane)

EverFlor AQ replaces water-based alkyd. It’s a water-based acrylic enhanced with silane adhesion promoters for improved bond on prepared substrates, available in Matt and Satin. AQ is ideal for light-to-medium duty projects needing quick drying and low odour, paired with Prime AQ as its dedicated primer.

Polyaspartic (Clear Topcoats)

Fast-curing, UV-stable clear topcoats that add excellent abrasion resistance and speed up return-to-service—perfect over epoxy colour coats and decorative flake systems.

What Paint to Use for Each Floor Type

| Floor/Substrate | Recommended Coating | Notes |

|---|---|---|

| Concrete (domestic garage) | 100% Solids Epoxy – Garage (performance) • PU (value) | Epoxy = highest durability/chemical resistance; PU is a strong, more economical option. Add anti-slip if needed. |

| Concrete (industrial/warehouse) | 100% Solids Epoxy – Industrial | Heavy-duty film; consider broadcast quartz for grip. PU topcoats or polyaspartic may be used depending on system design. |

| Power-floated concrete | Prime with EverFlor Prime PF (water-based epoxy) + epoxy/PU | Tight surfaces need mechanical grind or dedicated powerfloat primer for adhesion. |

| Oily or damp concrete | EverFlor Prime OT (oil tolerant) / Prime DT (damp tolerant) | Thorough degreasing still required; tolerant primers help bonding on imperfect substrates. |

| Green/new concrete | EverFlor Prime EW (WBE primer for green concrete) | Allows earlier coating schedules; always check moisture and curing times. |

| Wooden floors | PU 1K now; EverFlor PU Garage/Wood (Gloss/Matt) soon | Sand smooth, vacuum, spot-prime knots/tannins; consider subtle anti-slip. |

| Decorative flake | Epoxy colour + EverFlor HB FlakeShield + clear polyaspartic | Showroom finish with fast, UV-stable topcoat (EverFlor PA ClearGuard Ultra). |

| Light domestic refresh | EverFlor AQ (Matt/Satin) + Prime AQ | Low odour, quick drying; ideal for utility rooms and home workshops. |

Preparing Your Floor (By Substrate)

Concrete

- Clean & degrease: remove dust, laitance, oil and tyre marks (see EverFlor ConcrClean).

- Key the surface: grind or etch; power-floated slabs are too tight without mechanical keying or EverFlor Prime PF (water-based epoxy).

- Moisture: ensure dry substrate, or use Prime DT if residual moisture is present.

- Prime correctly: Prime DP for dusty/weak concrete; Prime OT for oil-affected; Prime EW for green concrete; Prime 4H (100% solids epoxy) for rapid return-to-service schedules.

Wood

- Sand to a uniform key; fill defects; vacuum thoroughly.

- Spot-prime knots/tannins; use Prime PU where a PU system is specified, then PU topcoats.

Tiles & Laminates

- Degrease, abrade glossy surfaces, remove dust.

- Apply a bonding/adhesion primer (EverFlor Laminate Primer / EverFlor Porcelain Primer, launching soon) before your topcoat (PU or AQ as appropriate).

How to Paint a Floor: Step-by-Step

- Mask & protect: tape skirtings and thresholds; protect doorways.

- Stir/mix thoroughly: if 2K, mix Part A+B exactly; respect pot life.

- Cut in edges, then roll thin, even coats—don’t flood the floor.

- Respect re-coat windows: follow minimum/maximum times for intercoat adhesion.

- Add anti-slip: stir-in additive for subtle grip or broadcast quartz for maximum traction (see below).

- Cure fully before vehicles/heavy loads. Foot traffic is sooner; full chemical/abrasion resistance needs full cure.

Anti-Slip Options

Every current floor paint we sell can be specified with an anti-slip profile. Choose based on risk level:

- System B (Stir-In Additive): subtle texture mixed into the paint—ideal for domestic, retail and light commercial.

- System A (Broadcast Quartz): broadcast aggregate into the wet coat, then over-seal—maximum traction for ramps, loading bays and wet zones.

Coverage, Drying & Curing (UK Conditions)

| Coating Type | Typical Coverage | Touch Dry* | Re-coat* | Full Cure* |

|---|---|---|---|---|

| 100% Solids Epoxy | 7–10 m²/L/coat | 6–12 hrs @ 15–20 °C | 12–24 hrs | 5–7 days |

| PU 1K (Solvent) | 8–12 m²/L/coat | 4–8 hrs | 8–16 hrs | 3–7 days |

| EverFlor AQ (WB Acrylic) | 9–12 m²/L/coat | 1–3 hrs | 4–6 hrs | 3–5 days |

| Water-Based Epoxy (EverFlor WEP) | 8–11 m²/L/coat | 1–2 hrs | 2–4 hrs | 3–5 days |

*Cooler temperatures and higher humidity slow drying. Always check the product label for exact guidance.

Common Mistakes & How to Avoid Them

- Skipping primer: especially on tight/smooth or contaminated surfaces (use PF/OT/DT/EW/AQ/PU primers as appropriate).

- Painting damp concrete: causes blistering and peeling; use Prime DT or wait to dry.

- Applying thick coats: traps solvent/water; use thin, even coats for better cure and adhesion.

- Ignoring re-coat windows: leads to poor intercoat adhesion.

- Inadequate degreasing: residues kill adhesion; use a proper degreaser (EverFlor ConcrClean).

Floor Paint FAQs

Can I paint power-floated concrete?

Yes—but you’ll need to grind to open the surface or use a specialist powerfloat primer, EverFlor Prime PF (water-based epoxy), before applying epoxy or PU topcoats.

How long before I can park on a newly painted garage floor?

Allow full cure—typically 5–7 days for 100% solids epoxy at 15–20 °C. You can walk on it sooner, but hot tyres and point loads need full cure.

Is epoxy always the best choice for concrete?

Epoxy is the performance leader for adhesion and chemical resistance, but it does come at a cost premium. For many projects, PU delivers an excellent, more economical balance of toughness and flexibility, while EverFlor AQ suits light-to-medium duty, low-odour refurbishments.

Do I need anti-slip?

Recommended for wet, sloped or high-traffic areas. Choose stir-in for subtle grip or broadcast for maximum traction.

Will paint hide cracks or holes?

No—repair first with the correct mortar or epoxy repair compound, then prime and paint. Coatings are protective, not structural.

Shop the Range (Available Now)

These coatings are in stock and ready to ship. All can be specified with an anti-slip option.

Water-Based Alkyd Floor Paint

Low odour, quick drying—great for light-to-medium domestic areas and refresh projects.

Note: Will be replaced by EverFlor AQ (WB Acrylic with silane) in Matt/Satin.

View • Anti-Slip Available

Solvent-Based PU 1K

Tough, flexible film with excellent abrasion resistance—ideal for wood, workshops and retail areas.

View • Anti-Slip Available

100% Solids Epoxy — Garage

High build, chemical and tyre-pick-up resistant. Ideal for domestic garages and workshops.

View • Anti-Slip Available

100% Solids Epoxy — Industrial

Heavy-duty film build for warehouses, production areas and high-traffic plant.

View • Anti-Slip Available

EverFlor: Coming Soon

High-Build Epoxy (HB)

- EverFlor HB Industrial

- EverFlor HB Rapid Industrial

- EverFlor HB ColdCure Industrial

- EverFlor HB Garage

- EverFlor HB Garage Rapid

- EverFlor HB Garage ColdCure

- EverFlor HB Factory

- EverFlor HB Factory Rapid

- EverFlor HB Factory ColdCure

- EverFlor HB FlakeShield — decorative flake epoxy system

- EverFlor HB AnimalCare Ultra

Epoxy Systems (WEP & ChemResist)

- EverFlor WEP — water-based epoxy

- EverFlor WEP Hygienic

- EverFlor WEP AnimalCare

- EverFlor ChemResist — Original

- EverFlor ChemResist — Acid Strength

- EverFlor ChemResist — Anti-Slip

- EverFlor ChemResist — Cold Cure

- EverFlor ChemResist — Rapid

Polyurethane & Polyaspartic

- EverFlor PU Garage Gloss

- EverFlor PU Garage Matt

- EverFlor PU Industrial Gloss

- EverFlor PU Industrial Matt

- EverFlor PU Wood Gloss

- EverFlor PU Wood Matt

- EverFlor PA ClearGuard Ultra — clear polyaspartic topcoat

- EverFlor PA ClearGuard Ultra Anti-Slip

Anti-Slip Systems

- EverFlor SafetyTread

- EverFlor SafetyTread Rapid

- EverFlor SafetyTread Cold Cure

- EverFlor TractionCoat Original

- EverFlor TractionCoat Hygienic

- EverFlor TractionCoat Coarse

Primers

- EverFlor Prime PU — primer for PU 1K

- EverFlor Prime OT — oil-tolerant epoxy

- EverFlor Prime DT — damp-tolerant epoxy

- EverFlor Prime DP — deep-penetrating epoxy

- EverFlor Prime PF — water-based epoxy for power-floated slabs

- EverFlor Prime 4H — 100% solids epoxy fast return primer

- EverFlor Prime AQ — dedicated primer for EverFlor AQ

- EverFlor Prime EW — WBE primer for green concrete

- Laminate Primer (coming soon)

- Porcelain Primer (coming soon)

Cleaners & Prep

Specialist

- EverFlor AQ — water-based acrylic with silane (Matt/Satin)

- EverFlor LineMark — line-marking paint